Template: Western Power Generator Performance Standards (GPS)

Template version: v7

Country:

AU

Software required:

Source: Western Power | Wholesale Electricity Market Rules (WEM Rules) | 1 April 2024

Background

The number and complexity of generation interconnections have increased during the energy transition. In an effort to ensure the adequate performance of generating systems and to ensure efficient design principles by utilising standards where possible, Western Power established Performance Standards in the WEM Rules. Western Power requires proponents to show compliance with these Technical Requirements, as well as other requirements - collectively referred to as "Generator Performance Standards (GPS)". This template includes a selection of tests to demonstrate compliance with these "Generator Performance Standards (GPS)".

Configuration

To use this template:

- Configure your Global Variables and Scenario Variables using gridmo's Model setup template.

- Download this template using the download button above and load the template into the gridmo Web App.

- Transfer your General tab data, Global Variables and Scenario Variables into this template using the 'Import' buttons in the gridmo Web App.

- Follow the below GPS-requirement-specific setup steps.

A12.2 Active Power Capability

The purpose of A12.2 is to demonstrate your generating system's ability to deliver the declared Rated Maximum Active Power continuously across a range of different conditions (e.g. connection point voltages and ambient temperatures).

- A simulation time of 300 seconds is "a period sufficient to capture all control or protection action".

- Auxiliary loads should be set to their maximum power demand.

A12.3 Reactive Power Capability

The purpose of A12.3 is to demonstrate your generating system's reactive power capability while operating across a range of different conditions (e.g. active power outputs, connection point voltages and ambient temperatures).

Demonstrating performance is split into two parts:

- Static studies: Generating static study unconstrained P-Q capability curves is typically completed using an in-built PowerFactory feature.

- Dynamic studies: Generating dynamic study constrained P-Q capability curves is completed using gridmo.

- Tests are conducted at infinite SCR and X/R.

A12.4 Voltage and Reactive Power Control

The purpose of A12.4 is to demonstrate your generating system's voltage, reactive power and power factor controller performance.

- A12.4.2.15: "5% step change to the Control System reference" is unclear for Qref and PFref steps. The Qref step size was chosen as 50% of the generating system reactive power capability defined in A12.3 (i.e. 50% × 0.484 x Maximum Rated Active Power). The PFref step was chosen as an equivalent size to the Qref step (i.e. PFref change from 1 to ±0.9719). For steps into limiters, this means that a 2.5% Vref step size is equivalent to 25% of the generating system reactive power capability defined in A12.3 (i.e. 25% × 0.484 x Maximum Rated Active Power).

- Although not specifically requested by Western Power, the Vref, Qref and PFref tests are conducted at both minimum/maximum SCR and X/R.

Step 1 - Q(V) droop curve | Choose grid voltage steps simulation time

Choose the grid voltage steps simulation time in the "Q(V) droop curve" tests which is sufficient for your generating system to settle. This simulation time will depend on your reactive power control system gains as well as your ramp up and ramp down control limits (e.g. expressed in MVAr/sec). If required, edit the simulation time of the relevant PowerFactory Dynamic, PSCAD™ and Plot Nodes.

Step 2 - Choose Qref and PFref values

Choose Qref and Qref values which correspond to a "...5% step change to the Control System reference" (see above for note). Note that PFref values may be in different units depending on your OEM model (e.g. radians, degrees, unitless). If required, edit the relevant Qref and PFref Commands.

To achieve the same reactive power step size, the PFref step value will need to change depending on the initial active power.

A12.5 Active Power Control

The purpose of A12.5 is to demonstrate your generating system's active power controller performance.

Step 1 - Choose Pref step sizes

Pref step sizes are chosen as ±5% as default. As outlined in [2], "Generating System characteristics may require the step changes to be larger. Larger changes may be considered to more accurately determine equipment performance (e.g. A step size of 10% or 20%)."

A12.6 Inertia and Frequency Control

The purpose of A12.6 is to demonstrate your generating system's frequency control capability.

- Only SMIB studies have been completed. Network-wide studies may be added to further demonstrate that the response is adequately damped.

- Frequency 'steps' are completed at a 4Hz/s ramp rate.

- A12.6.1.11(b): The maximum response delay is assumed to be 250ms.

A12.7 Disturbance Ride Through for a Frequency Disturbance

The purpose of A12.7 is to demonstrate your generating system's ability to maintain Continuous Uninterrupted Operation (CUO) for a particular frequency operating standard. We've also included tests to ensure that some form of frequency protection exists.

- Tests are conducted at infinite SCR and X/R.

- Tests are conducted using a playback generator with infinite inertia.

- All frequency 'steps' are completed at a 4Hz/s ramp rate.

- Ride Through RoCoF: The test methodology involves ramping from 50 Hz to the test frequency at 1 Hz/s over the simulation time of 5 seconds to 6 seconds. The RoCoF is then applied at the simulation time of 10 seconds.

Step 1 - Choose frequency operating standard

Choose a frequency operating standard in accordance with Appendix 13 of [1]. The frequency operating standard from Table 1 of Appendix 13 of [1] has been chosen by default. If an alternate operating frequency standard is chosen, update the relevant SMIB playback tests in the Nodes.

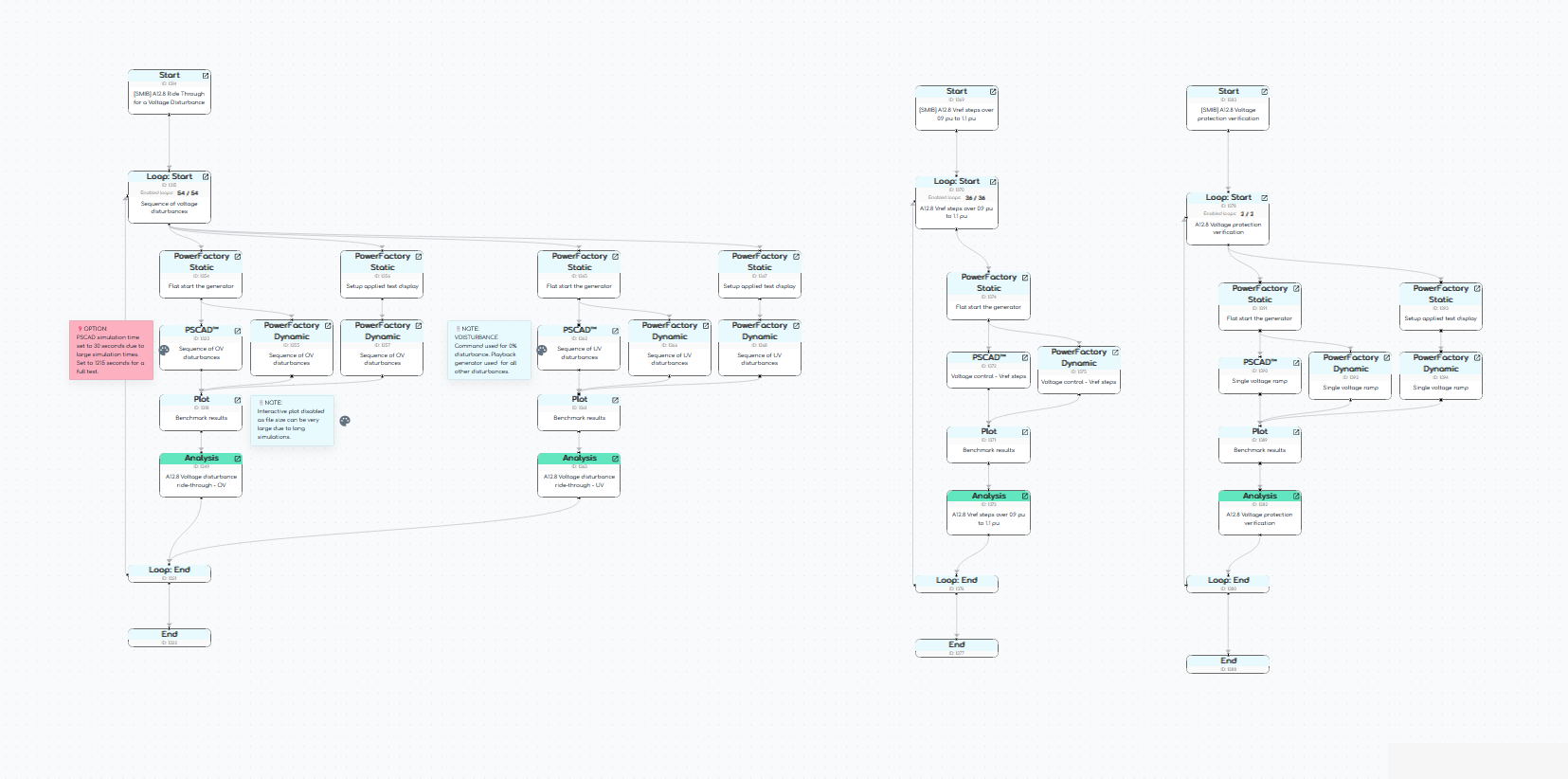

A12.8 Disturbance Ride Through for a Voltage Disturbance

The purpose of A12.8 is to demonstrate your generating system's ability to maintain Continuous Uninterrupted Operation (CUO) for particular voltages at the connection point. We've also included tests to ensure that some form of voltage protection exists.

- Ride-through tests for each voltage range are chosen such that the time spent within that range includes any time spent in the more onerous ranges.

- A12.8.2.1(a): Voltage exceeding "130% of nominal voltage" is represented by 132%.

A12.9 Disturbance Ride Through for Multiple Disturbances

The purpose of A12.9 is to demonstrate your generating system's voltage disturbance ride-through performance. There are several criteria when assessing this performance:

- FRT transition bands | SMIB: Smoothly enter and exit a fault ride-through mode (known as

transition band testsin this template). - Balanced voltage disturbances | SMIB: Response to balanced voltage disturbances must meet

Kpocgain value,Iqrise time,Iqsettling time,Ppocrecovery time and CUO requirements. - Unbalanced under-voltage disturbances: Response to unbalanced under-voltage disturbances must meet

Kpoc_neggain value,Iqrise time,Iqsettling time,Ppocrecovery time and CUO requirements. - Series of disturbances | SMIB: Response to a series of balanced and unbalanced faults.

- Only SMIB studies have been completed. Network-wide studies may be added to further demonstrate performance.

- Studies have not been repeated for all PPC reactive power control modes (i.e. voltage droop control, reactive power control and power factory control) because these tests are primarily investigating the performance of fault-ride through modes where the PPC reactive power control mode is overridden/'frozen'.

Step 1 - Choose clearance times for "3. Under-voltage disturbances"

The default clearance time is 450 ms. You may choose a different clearance time depending on the network protection systems.

A12.10 Disturbance Ride Through for Partial Load Rejection

The purpose of A12.10 is to demonstrate your generating system's ability to maintain Continuous Uninterrupted Operation (CUO) during and following a particular power system load reduction event or a separation event with an equivalent impact.

- If your generating system is comprised of only grid-following asynchronous plant, then you could instead propose compliance with A12.10 via demonstrating compliance with A12.7. Specifically, you could assert that any system separation event, regardless of load reduction of pre-disturbance level cannot exceed the frequency operating standard and ROCOF as per A12.7.

- However - if you have a synchronous plant or grid-forming inverters in your generating system, the inertia of your generating system may need to be considered in your generating system's ability to maintain continuous uninterrupted operation during a partial load rejection event.

We don't currently support network studies for PowerFactory.

A12.11 Disturbance Ride Through for Quality of Supply

The purpose of 12.11 is to confirm that your generating system does not disconnect as a result of specified voltage fluctuation, harmonic voltage distortion and voltage unbalance levels.

We don't currently provide tests for 12.11. Additionally, compliance is often demonstrated via product information obtained via your OEM.

A12.12 Quality of Electricity Generated

The purpose of A12.12 is to confirm that your generating system's output does not exceed specified voltage fluctuation, harmonic voltage distortion and voltage unbalance limits.

We don't currently provide tests for A12.12.

A12.13 Generation Protection Systems

The purpose of A12.13 is to confirm that your generating system has adequate protection systems.

We don't currently provide tests for A12.13. Additionally, compliance is often demonstrated via design reports.

A12.14 Remote Monitoring Requirements

The purpose of A12.14 is to confirm that your generating system has adequate remote monitoring.

We don't currently provide tests for A12.14.

A12.15 Remote Control Requirements

The purpose of A12.15 is to confirm that your generating system has adequate remote control.

We don't currently provide tests for A12.15.

A12.16 Communications Equipment Requirements

The purpose of A12.16 is to confirm that your generating system has adequate communications equipment.

We don't currently provide tests for A12.16.

A12.17 Generation System Model

The purpose of A12.17 is to ensure the accuracy and robustness of the generating system's model. You should ensure that your models meet the requirements of [4]. Where possible, we have included tests to assess the compliance of your model.

Assumptions

- Generally, Ideal Generator Performance Standard is assumed for all tests and Analysis Nodes within the template.

- Template has primarily been configured for asynchronous intermittent generating systems. Additional tests required for synchronous generating systems have been included and disabled by default.

- By default, the selected number of loops (i.e. operating conditions and/or test variations) is a subset of the required tests in an effort to reduce simulation time when getting initial results. For submission, you may want to select a greater number of loops.

Sources

- [1] Western Power | Wholesale Electricity Market Rules (WEM Rules) | 1 April 2024

- [2] Western Power | Generator Performance Standards: Guideline for the Assessment of Technical Requirements | Version 2 | 30 January 2023

- [3] Western Power | Technical Rules | Revision 3 | 1 December 2016

- [4] Western Power | Facility Model Guidelines - Transmission Grid Strategy and Planning | Revision 1 | 30 April 2024

Revision history

Version 7 | 30 January 2026

Improvements- Added Action Nodes.

- Replaced deprecated

RISE_T,SETTLE_T,COMMENCEMENT_Tcommands in all Plot Nodes withRISE_TIMEandSETTLING_TIMEcommands.

- 12.3 Reactive Power Capability: Changed

CONTROLcommand for controlling the Thévenin equivalent generator to aSETcommand as per latest updates to WECC solar model. - 12.4 Minimum equivalent gain: Removed excessive

TAT=arguments inADVBANDScommands in Plot Node1124. - 12.5 Active Power Control: Removed excessive

TAT=arguments inADVBANDScommands in Plot Node1134. - 12.7 Ride Through for a Frequency Disturbance: Fixed

TAT=arguments inADVBANDScommands to align with the time at which frequency disturbances occur in Plot Node1248.

Version 6 | 16 April 2025

Fixed- Added missing Internode Variable for HVRT flag output in Node

1410. - Added missing Internode Variable for LVRT flag output in Node

1416. - Fixed incorrect Internode Variable name in Analysis Node

1413for LVRT entry/exit voltages. - Fixed incorrect Internode Variable name in Analysis Node

1415for HVRT entry/exit voltages.

Version 5 (v1.4.20) | 21 January 2025

- Updated descriptions in template for Nodes, Plot subtitles and file names to better describe tests.

- A12.9 FRT transition bands: Split the Plot Nodes which were calculating the LVRT and HVRT enter/exit times so that there is one per power systems software (i.e. PowerFactory and PSCAD™). There was an error where the LVRT and HVRT enter/exit times were only calculated in PSCAD™ and these values were used to output the Vpoc values for both PowerFactory and PSCAD™.

- A12.4: Error bands on reference step into limiter tests had incorrect

AT=Arguments:TAT=25, TAT=35.

Version 4 (v1.4.16.6) | 23 September 2024

- 12.9: i_iq_settling_time calculation during faults incorrectly had END_T Argument as 15 seconds. This was changed to 5.449 so that the settling time value is calculated within the applied disturbance duration.

Version 3 (v1.4.16) | 27 August 2024

- Included tests for Synchronous Generating Systems.

Version 2 (v1.4.15) | 28 June 2024

- A12.3: Update Plot subtitle to include description of Pref and Qref.

Version 1 (v1.4.14) | 29 May 2024

- First release